History - 61 Years of Innovation

1946

New Brunswick Tool & Die Company opens its doors as a 4-man shop in New Brunswick, N.J., USA, started by brothers David and Sigmund Freedman.

1949

Graduate students of Dr. Selman Waksman at Rutgers University attempt to isolate an antibiotic-producing bacterium for treating infection, but are stalled by frequent failure of their test-tube shaking apparatus. The Freedman brothers offer to build a better machine – the New Brunswick Shaker is born.

1952

Dr. Waksman is awarded the Nobel Prize in Medicine for isolating streptomycin – the first antibiotic successful in treating tuberculosis - creating an instant demand for the New Brunswick Shaker. Over the next 25 years, NBS equipment goes on to be used in the discovery and production of virtually every antibiotic in commercial use.

1950 & 60s

Reciprocating shakers for more rigorously mixing cultures and chemicals; the first water bath shakers which provide temperature control for culturing micro-organisms; multi-tiered shakers for mass screening antibiotic compounds and producing vaccines; Psychrotherm – the first refrigerated incubator shaker; the Model G25 large-capacity console-style incubator shaker, and G76 water bath shaker – which unbelievably are still operating in labs around the world, some forty-plus years after they were first introduced.

The world’s first commercial fermentors – single vessel and multi-vessel systems, a 40-liter pilot plant fermentor and a continuous culture apparatus are introduced. Autoclaves for vessel sterilization, freeze dryers, colony counters and the first tissue culture roller drums are also developed.

1970s

New product “firsts” abound:

NBS designs the world’s first microbiological air samplers. Our slit-to-agar air samplers have been used in the Gulf War to aid in the detection of biological warfare, in Post Offices for the detection of anthrax, and in clean room environments to ensure the sterility of products during the manufacturing process.

NBS custom-builds the world’s first major “cell culture factory” for the University of Alabama, used to grow lymphoblastoid cells for the production of vaccines.

1980’s and 1990’s

NBS introduces CelliGen - a benchtop bioreactor specialized for animal cell culture and a pre-cursor to the CelliGen Plus. Over the years, enhancements such as a new, low-shear Cell Lift Impeller and packed-bed option enable researchers to dramatically increase product yields over conventional technologies.

NBS introduces the first automated benchtop agar sterilizing system. The AgarMatic is a smaller version of our original floor model sterilizer, and when coupled with our new, automated PourMatic dish filler, provide hospitals and clinics with a labor-saving system, capable of sterilizing, pouring and stacking 320 plates in under an hour.

NBS develops the world’s first microprocessor-controlled shakers. Innova® shakers mark a new era in the use of microchips to precisely control equipment setpoints, alarms, running time, speed and temperature. NBS has subsequently developed over a dozen new or replacement Innova shaker models, with ever-enhanced capabilities, continuing their role as our flagship products.

2000 – Our first stackable shakers are introduced. Benchtop Innova 4200/4230 and large-capacity Innova 4400/4430 offer dual-temperature programming to automate switching between two temperatures on a programmed basis.

2001 – We introduce the BioFlo 110, a benchtop fermentor/bioreactor with modular design allowing system expansion as needs or budgets grow. Capable of regulating up to four vessels simultaneously, the advanced controller enables users to view and change process parameters in English, French, German or Spanish.

2002 – Researchers, working in conjunction with the World Health Organization, develop a new low-cost method of producing human rabies vaccine, helping to prevent a disease which kills 30,000 people each year. The protocol, which uses a 30-liter NBS bioreactor equipped with Cell Lift impeller, turns out a million doses of vaccine and requires just three technicians to operate.

2003

NBS introduces the world’s first modular, large-scale fermentors, cutting lead time for order to delivery from an industry-standard six or more months to an average of just 12 weeks. BioFlo Pro fermentors additionally make it easy to perform upgrades, at any time, pre- or post-delivery.

For smaller scale needs, NBS introduces the full-featured BioFlo 410, a sterilizable-in-place benchtop fermentor/bioreactor with touchscreen interface, providing all the capabilities and features of a large-scale system in a benchtop unit.

2005

The Innova U360, a new slender upright ULT freezer is launched, designed to fit where other freezers cannot. It rounds out a line of 10 freezer models.

NBS introduces an inexpensive, disposable cell culture system known as FibraStage™. The labor-saving system uses just one to four disposable bottles, pre-filled with NBS’ FibraCel® disks, to produce yields equivalent to dozens of spinners, or hundreds of T-Flasks or rollers.

The BioFlo Pro line is expanded again, this time to include a series of modular, large-scale bioreactors for cell culture.

2006

NBS introduces two new CO2 Incubators - Innova CO-170 and Excella CO-170, offering greater internal space without impacting footprint.

Fourteen new shakers are introduced, including four new bench and floor model shakers in our top-of-the line Innova range; two new space-saving stackable I-26 & I26R incubator shakers; and an all new Excella™ line (shown) providing an economical alternative to Innova models

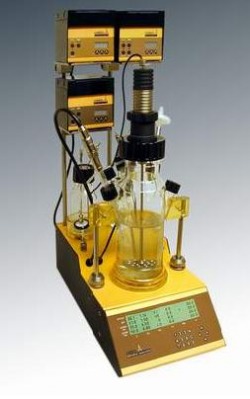

The next-generation BioFlo 310 fermentor/bioreactor is brought to market, capable of controlling up to four fermentors from an easy-to-use touchscreen controller. For the first time on the benchscale, the fermentor can integrate signals from up to ten external devices, including gas analyzers, sensors and scales, for optimized process control.